Heating and cooling networks

Supplying several buildings, blocks of flats or entire cities with cost-effective and sustainable heating and cooling - this is made possible by district heating and cooling or local heating and cooling. Just as important as the production of heat and cold in the combined heat and power plant is the distribution of the tempered water via a pipe system. Heat and cold losses pose a major risk here. The higher these losses are, the more energy has to be used in the combined heat and power plant to generate the heat and cold, which has a negative impact on the CO2 footprint and costs. aquatherm offers an innovative modern PP piping solution for 4th generation district heating and other projects with operating temperatures up to 80 °C.

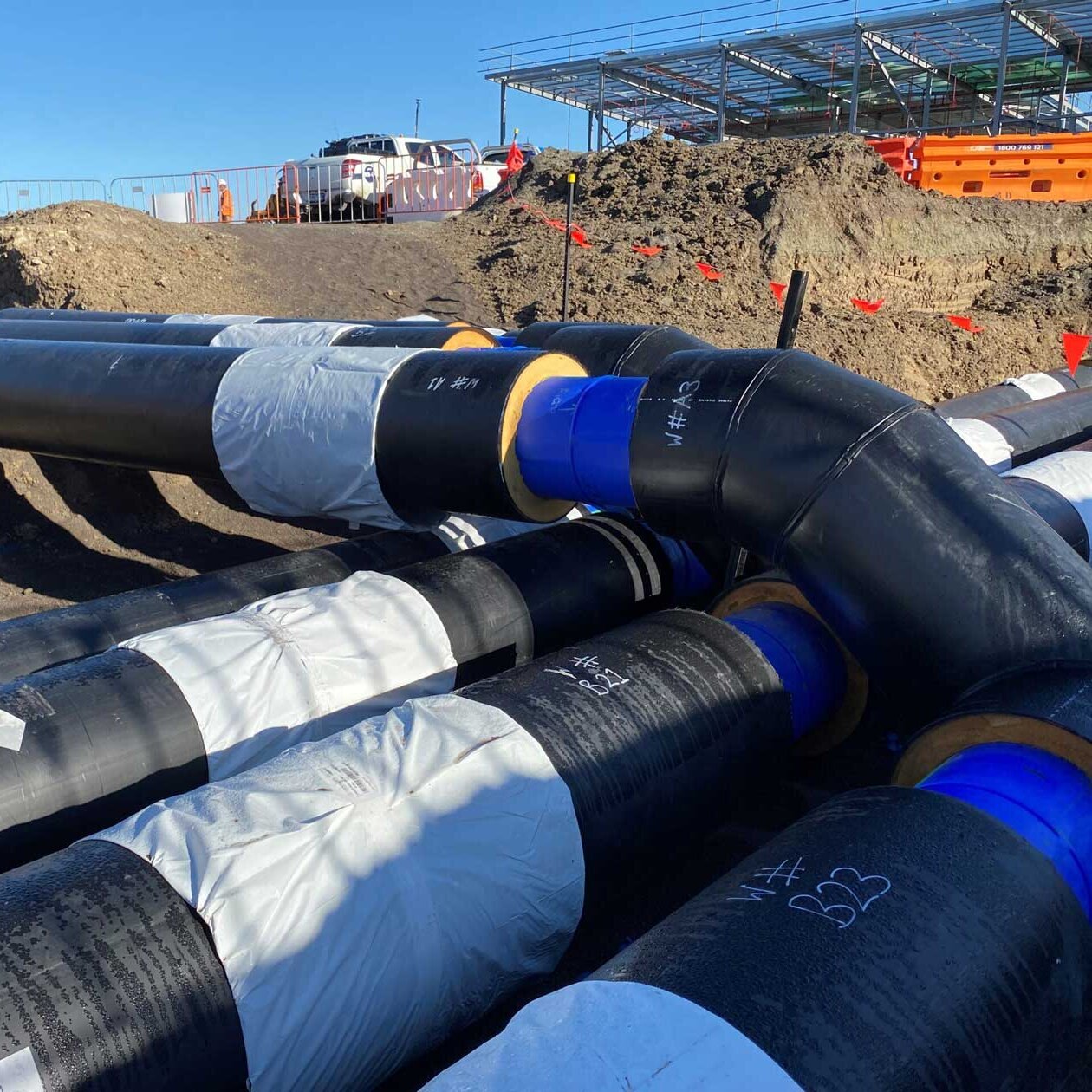

The factory pre-insulated polypropylene piping system is a buried version that helps to transport heating and cooling water safely and efficiently over longer distances. aquatherm energy is self-compensating. It can be installed without having to compensate for temperature-related changes in length. The corrosion-free system also scores points for being lighter than steel and quick to install.

One-stop-shop solution

aquatherm offers a complete solution up to DN 355 from one source:

- Transport pipes

- Distribution pipes

- All types of pre-insulated bends and outlets

- Shrink joints

- Fully PP-welded house connections with pre-insulated T-pieces

- Drilling of house connections with open T's and foaming on site

- Hot tapping - i.e. making additional connections in a pressurised system - i.e. without any disruptions

Solutions

aquatherm offers pre-insulated pipe systems in different pressure stages in sizes from 32 - 355 mm. In addition, there are pre-insulated fittings for bends and T-pieces, as well as shrink sleeve sets WTD with fittings for 32 - 125 mm service pipes.

Prefabricated parts

Bend 45°

Bend 90°

Branch

Overhang branch

Reduced branch

Reduced jump-over branch

Self-compensating pipe system for underground installation

Due to it's lower modulus of elasticity, aquatherm energy can be installed without compensating for linear expansion. This means only low stresses are generated in the polymer medium pipes which allows aquatherm energy to be directly buried without the need to compensate for expansion. The low expansion forces are absorbed by the material without any detrimental effect.

Advantages

- Corrosion free system

- No need for steel welders

- Safer to work with as pipes are often connected above ground (not in trench)

- Less depth in trench required

- Less complex testing procedures

- Quick installation, therefore reduced installation costs of the heat network

- Flexible installation thanks to polypropylene, often without bypassing existing pipework and other structures

- Less weight compared to steel

- Fewer open excavations required due to faster installation

- Significantly less pumping power required due to elimination of expansion loops and smooth inner surface compared to steel pipes