Unusual challenges for architects and planners

aquatherm black cools and heats the new Luisenhöhe health resort

The "Luisenhöhe - Black Forest Health Resort" has been built in the midst of the natural landscape of the UNESCO Black Forest Biosphere Reserve in South of Germany. The modern resort in Horben near Freiburg im Breisgau, which houses 61 rooms and 22 suites, is operated by BCW Hotels & Resorts GmbH. It offers its guests an extraordinary health and nature experience on a high plateau on the western slope of the Schauinsland massif at an altitude of 600 m - all under sustainable aspects.

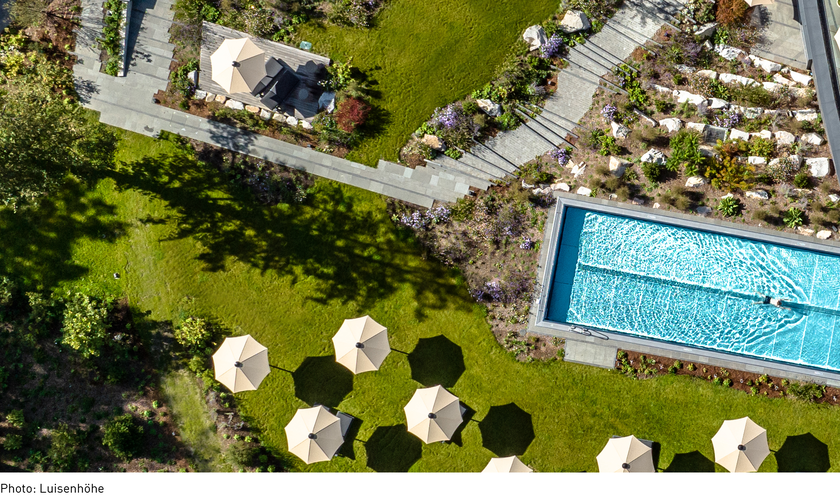

Under the motto "Modern Health & Nature Luxury", guests are to experience a health and nature consciousness with the "new luxuries" of time, uniqueness, authenticity, flexibility, creativity and individuality. The hotel complex covers 18,500 square metres. Highlights include a spa with indoor and outdoor areas, panoramic view saunas, a panoramic regeneration pavilion in the mountain forest, a 25 m outdoor pool, indoor and outdoor experience gastronomy, a panoramic terrace, and an inner courtyard with a view of the natural garden. The banquet and conference facilities invite you to smaller events and exclusive "summit meetings".

The cost of the new building, which has rewritten the Luisenhöhe chapter in Horben, was around 60 million euros. After all, the Luisenhöhe was built as a chalet-style spa hotel back in 1896 which was partially destroyed by fire in 1908, and then used as a retirement home a few years later. The Gesundheitsresort Schwarzwald Luisenhöhe GmbH & Co KG acquired the building and grounds in 2015 to plan a health and nature resort there. After demolition work on the old Luisenhöhe began in 2018, the groundbreaking ceremony for the new building project took place in October 2019.

The entire concept of the new building is based on resource-saving materials, techniques, energies and working methods: Special accents are set by the renewable energy supply with a large geothermal probe field under the underground car park, the heat recovery and the generous near-natural retention areas such as the greening of all roof surfaces with additional water retention and infiltration functions. In addition, a variety of nature conservation and species protection measures make the building project special.

The technical building equipment was designed by the HTG Petra Haberland planning office from Euskirchen. Geothermal energy is the main energy source used to heat and cool the hotel complex. It is supplied with four brine-water heat pumps for low and high temperature heat. In addition, there is an air heat exchanger for regenerating the ground and recoolers in the outdoor area. Under the underground car park there is a field of 55 geothermal probes down to a depth of around 145 m. These cover the entire energy demand for the building, cooling and heating the hotel, and the outdoor pool. The power supply is provided by a dedicated 1000 kVA transformer.

The public rooms on the ground floor and partly on the first floor are tempered on 1620 sqm via a heating and cooling ceiling from aquatherm. The conference areas and the spa and fitness areas on the ground floor are additionally cooled through activated wall surfaces. In all cases - for heating and cooling - the system aquatherm black was used. The black registers, made of the corrosion-resistant plastic polypropylene, ensure an optimal room temperature in cooling and heating mode through an even exchange of radiation with the room's surrounding surfaces. Draughts or dust swirls are excluded by this process.

Due to the small installation distance of the register pipes and the high surface density of aquatherm black per square metre, the system can be operated with lower flow temperatures than conventional heating systems or higher flow temperatures than other cooling systems. In combination with its fast response time, it enables particularly efficient and energy-saving operation under changing conditions. Around 600 square metres of the system were installed in the Luisenhöhe. This relatively small number of square metres in relation to the total area of the resort is sufficient to heat or cool all the necessary areas of the hotel.

“Few right angles, a lot is curved”

One challenge in the planning was the architecture of the new building, which is oriented towards the ridges of the Black Forest: "The building and its individual rooms have few right angles. A lot of it is curved, round or turned," explains Thomas Bille, head of the "Consulting & Service" planning department at aquatherm. "We therefore had to adapt our system to the conditions on site, which was easily achieved through appropriate planning." In concrete terms, the individual elements of the system were manufactured at the aquatherm headquarters in Attendorn in southern Westphalia, to fit precisely in a wide variety of dimensions so that they could be inserted into the ceilings and walls in the building. The planning of the hydraulic connection was also carried out by aquatherm. aquatherm black also fits into the Luisenhöhe concept in terms of sustainability: the heating and cooling system is made of polypropylene, one of the two most important standard plastics. Life cycle analyses in accordance with ISO 14040 are used to examine the impact of raw material production on the environment. Studies show significantly lower CO2 emissions from polypropylene pipes compared to other raw materials, especially steel.

aquatherm has been processing this raw material, which is characterised by a long service life and very good environmental compatibility and recyclability, for around 50 years. The company has had an ISO-compliant life cycle assessment carried out for four product lines, including aquatherm black, which was verified by an independent institute. The environmental product declarations drawn up on the basis of these life cycle assessments confirm the low ecological footprint of aquatherm products compared to other systems.