TCF Bank Stadium warmly welcomes Minnesota Vikings with aquatherm piping system – Stable even at high operating temperatures - sports stadiums all over the world claim to offer optimal conditions for athletes.

Cold weather and football just seem to go together, but frozen fields and football have a tendency to draw complaints, especially from NFL players who know that a frozen field is about as cushy as a slab of concrete. That put the Minnesota Vikings, homeless last season (they had played previous seasons in the re-inflated Metrodome following the roof ’s collapse in 2010), between a rock and very hard place when it came to relocating to TCF Bank Stadium (home of the University of Minnesota Golden Gophers) for the 2014 and 2015 NFL seasons. After all, Brett Favre played his last career game there, sustaining a head injury when Chicago Bears Corey Wootton slammed him into the frozen TCF turf.

While aquatherm piping systems have been used on professional athletic fields throughout Europe, this installation would mark the brand’s debut on a professional football field in the United States. It was not a decision that anyone took lightly during this highly collaborative process between the Vikings management, the University of Minnesota, and a host of engineering and installation professionals.

“As we took a closer look, we began to see that this product could meet and even exceed some of the interesting challenges of this project.”

Those challenges included working with the existing substrate beneath the Gopher’s synthetic turf field. Most heated synthetic fields have several inches of sand as a base, which helps to contain the heat, but TCF had 12 to 18 in. of aggregate. This type of base has many voids between the particles. All that open space creates a pathway for heat loss away from the surface. This meant that the heating pipes would have to be installed closer to the field surface and the heating temperature of the fluid would have to be higher than what traditional polypropylene or PEX tubing can handle.

Aquatherm Blue, however, is safe to use in applications from -5°F to 200°F (depending on pressure rating) with the company’s multilayer faser composite, a fiberglass extruded layer that allows the pipe to remain rigid at temperatures that would cause other thermoplastic pipe systems to break.

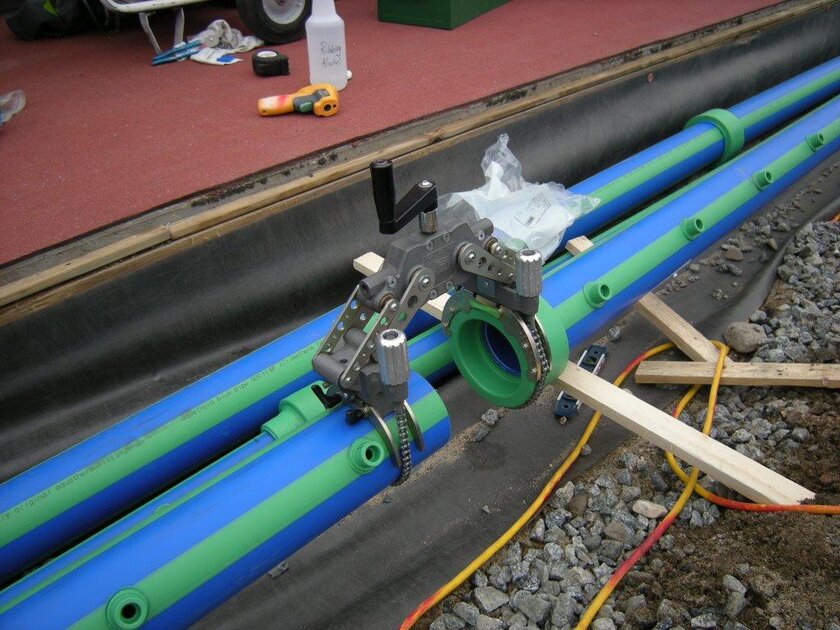

The use of aquatherm also eliminated the need for roughly 4,000 mechanical joints, most of which were to be buried beneath the playing field. aquatherm pipe and fittings do not rely on mechanical connections.

Solid connections are particularly important whenever glycol-based heat transfer fluids are used because the addition of glycol to water lowers the surface tension, thereby increasing the propensity for leaks to materialize. A “water tight” seal is not always as tight when glycol is present. aquatherm allowed workers to transform several hundred sections of pipe and thousands of fittings and manifolds into one seamless fluid transport system.

Harris Mechanical of St. Paul, MN, was the mechanical contractor responsible for installing the field piping and associated mechanical equipment. Despite the fact that no one from the company had ever used aquatherm before, the team managed to install the entire piping system in a matter of weeks and pass their first official pressure test without a single leak.

Given the tight schedule and the overall complexity of the system, it was fortunate that installers were able to stick with one pipe material for the entire system, from the 8-in. hot water supply pipe to the .in. nominal (20 mm) pipe installed in the field. Traditional thermoplastic systems are not available in such large sizes and would have required various transitional points between piping materials.

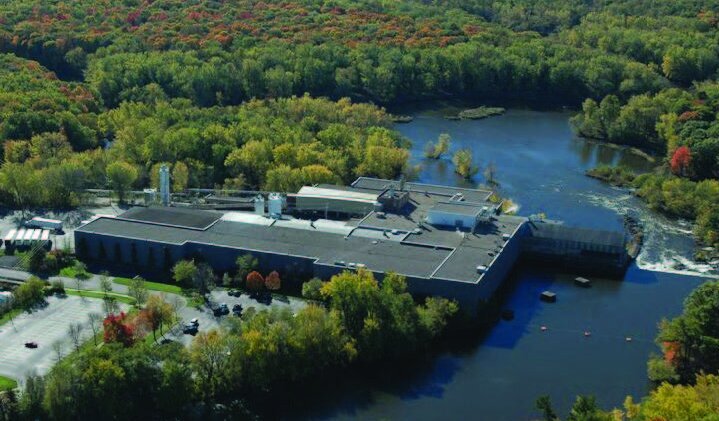

Bell & Gossett shell and tube heat exchangers, housed in an adjacent equipment room, serve as the heat source for the field. Roughly 7,000 gal of the DOWFROST HD inhibited propylene glycol mixture are pumped through the heat exchanger tubes, supply piping, and loop field. The 50% solution of DOWFROST HD and water has an effective operating temperature range of 0°F to 325°F and provides freeze protection down to -30°F and burst protection to -60°F. The system is designed to deliver approximately 10-MMBTU at design conditions, delivering 120°F water to the field via Bell & Gossett pumps with ABB VFDs.