Air conditioning concept for "green" logistics hall relies on optimally coordinated components.

The logistics company DISTRIBO works with particularly sensitive products from the life sciences sector. These must be stored at a constant temperature of between 15 and 25 degrees all year round. Thanks to the cooperation between planners, plant engineers, craftsmen and manufacturers of products in the field of heating and cooling, all requirements in the field of air conditioning were met during the construction of a new logistics hall. In addition, a "green" building was created that not only uses significantly less energy than comparable halls, but is even operated in an energy-positive way.

DISTRIBO was founded in Göttingen in 2003 and is a joint venture between the technology group Sartorius AG and the logistics service provider ZUFALL logistics group. DISTRIBO is responsible for the shipment of laboratory and process technology products as well as the production supply of all Sartorius sites in Göttingen. Due to the growing market of biotechnology, a new logistics hall with an adjoining office building and service workshop was required.

In order to offer DISTRIBO the best possible solution in terms of constant temperature and energy efficiency, the planning office Malte Weidemann, Metternich Haustechnik GmbH, Aii Allgemeine Industrieboden + Instandsetzungs GmbH and aquatherm GmbH have developed a concept for the air conditioning of the new logistics hall. This consists of several building blocks that are interlinked and optimally coordinated with each other.

Combination of photovoltaics, heat pumps and ice storage

"The planning challenge was to cover the building's high heating and cooling requirements," explains Malte Weidemann. Together with Metternich, he and his team opted for a combination of photovoltaic systems, heat pumps and an ice storage system. The functional principle of the ice storage system: When the physical state changes from liquid water to solid ice, a large amount of heat and therefore energy is released. Heat pumps make use of this energy as a heat source. Due to an interplay of heat extraction and regeneration, the freezing process can be repeated several times. At the end of the heating season, the existing ice core provides a free cooling option for the property.

Three heat pumps with a total output of 540 kW will be housed in the technical centre of the DISTRIBO logistics hall. The ice energy storage unit has a diameter of 18 metres and a height of 6 metres. Metternich installs the entire building technology, including the heat pumps, dry coolers, the required heating and cooling buffers, the ventilation system and the heat exchangers. In order to efficiently manage the various energy sources and guarantee a high degree of efficiency of the system, prefabricated hydraulic modules are installed. These modules are offered by Building Equipment Cologne (BE-Cologne) ready for installation for various system sizes. A total of nine modules - three source management modules, heat pump modules on the primary side and heat pump modules on the secondary side - will be used.

Piping with aquatherm blue made of polypropylene

The entire piping to and from the ice energy storage system and the individual elements of the air conditioning concept as well as within the hydraulic modules is carried out with a product from aquatherm GmbH: aquatherm blue. The piping system made of corrosion-resistant polypropylene plastic is characterised by high temperature resistance. "This was very important for the project, as temperature differences of -10 and +40 degrees Celsius occur," says Malte Weidemann. Depending on the requirements, the long distances to the ice storage tank are installed with the pre-insulated aquatherm energy, which contains aquatherm blue as a medium pipe, but is additionally insulated with PUR foam and enclosed with an HDPE casing pipe, and the uninsulated version. Malte Weidemann: "The combination of the insulated and non-insulated variants is no problem, as the same pipe, aquatherm blue, is used in both cases." When the polypropylene system is welded, the pipe and fitting merge into a homogeneous, material-locked unit. This ensures the highest level of safety and service life.

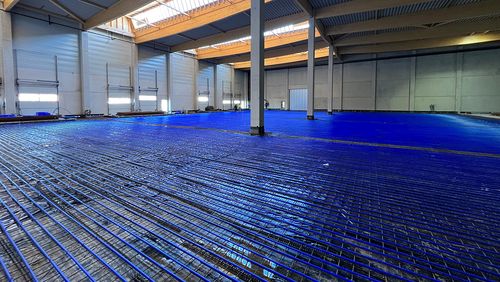

Industrial underfloor heating on 10,000 square metres

Another important component of the climate concept is the activation of the concrete core: In this special form of underfloor heating, the entire volume of the approximately 20-centimetre-thick concrete slab of the new logistics hall is used for heating and cooling. This ensures an even temperature and also saves energy. Aii – Industrieboden- und Instandsetzungs GmbH is building a total of 10,000 square metres of absolutely joint-free industrial flooring. Once again, the aquatherm blue piping system will be used, which will be installed with the Tichelmann installation and ensure even heat distribution. The system is also used in the workshop and office wing on an area of around 3,000 square metres.

Thanks to the extensive air-conditioning concept, the construction project achieves energy class E40+. This means that more than 60% less energy is required compared to other conventional buildings of this type.