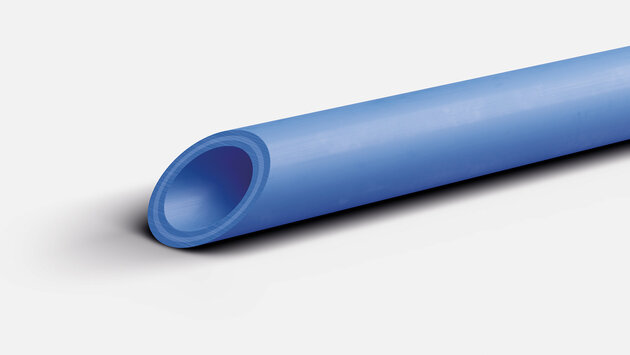

What can AQUATHERM BLUE do?

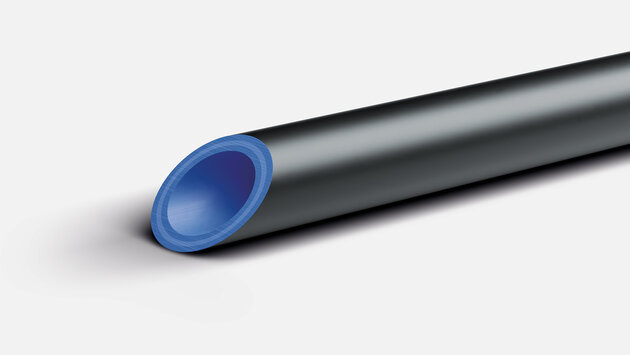

aquatherm blue is made of corrosion-resistant polypropylene (PP) and is the specialist for the transport of cooling and heating media in closed systems and is therefore particularly suitable for various industrial applications. The physical properties of the plastic are tailored to the special needs of the heating and cooling sector.

The material is characterised by high temperature and pressure resistance. Thanks to its exceptionally good welding properties, the pipe and fitting fuse to form a homogeneous, materially bonded unit. This results in maximum safety and service life. In combination with the extensive range of fittings, the system includes all components for the pipe performance installation of air conditioning and heating systems as well as for plant engineering.

What should you know about the technical features of AQUATHERM BLUE?

The diameter of the PP pipe determines its location and intended use. In order to be able to lay a pipeline from the connection to the outlet, the pipe diameter of the individual pipes and fittings must be compatible with each other.

aquatherm blue S: Ø 20-32 mm

aquatherm blue MF: Ø 20-25 mm

aquatherm blue MF UV: Ø 20- 25 mm

aquatherm blue MF OT: Ø 20- 25 mm

aquatherm blue MF RP: Ø 32 - 630 mm

aquatherm blue MF RP UV: Ø 32 - 630 mm

aquatherm blue MF RP OT: Ø 20 - 250 mm

The SDR (Standard Dimension Ratio) is a ratio indicating the resistance to pressure. In order to guarantee a certain pressure resistance, a certain maximum SDR number is necessary, depending on the type of material. The following applies: the greater the wall thickness, the smaller the SDR number and the more pressure-resistant the plastic pipe. The unit indicates the ratio between outer diameter and wall thickness of a pipe. aquatherm blue is available in the following SDR sizes:

SDR 7.4: aquatherm blue S | aquatherm blue MF | aquatherm blue MF UV | aquatherm blue MF OT

SDR 9: aquatherm blue MF RP | aquatherm blue MF RP UV | aquatherm blue MF RP OT

SDR 11: aquatherm blue S | aquatherm blue MF RP | aquatherm MF RP UV | aquatherm MF RP OT

SDR 17.6: aquatherm blue MF RP | aquatherm blue MF RP UV

aquatherm blue is made of corrosion-resistant material. This considerably extends the service life of the pipeline, for example for an air conditioning system. The material of aquatherm is characterized among other things by its special high heat and extraction stability. The physical and chemical properties are adapted to the special needs of the heating and cooling sector. Due to the exceptionally good welding properties, pipe and fitting fuse to form a homogeneous, materially bonded unit; this has made the material fusiolen® famous worldwide.

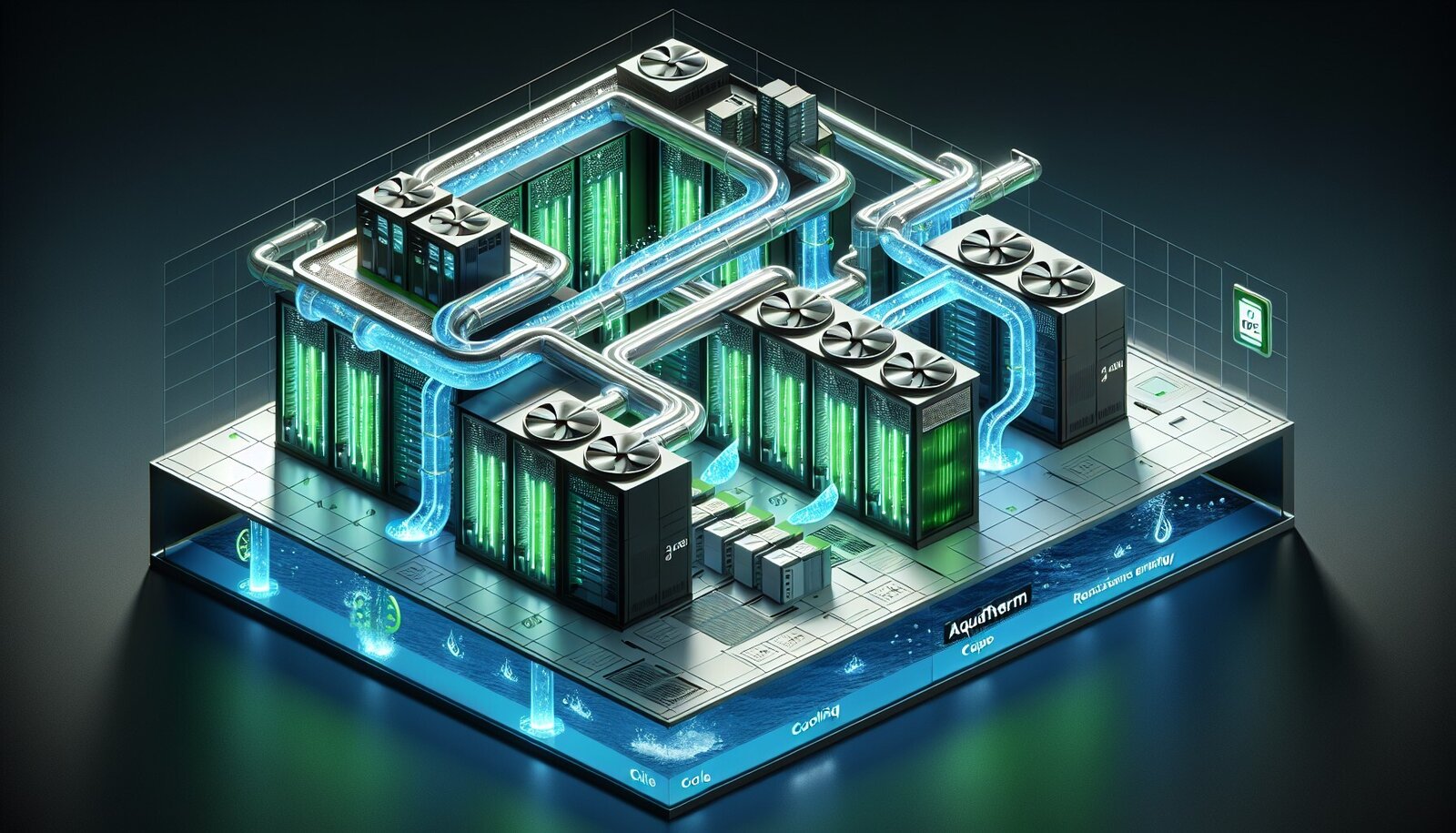

In combination with the aquatherm fittings, the system provides all components required for the piping installation of air conditioning, refrigeration, heating systems, and industrial applications:

• Pipes in straight lengths and/or coils

• Fittings

• Flanged joints

• Water point connections and accessories

• Welding devices and machines

• Weld-in and weld-on saddles

• Manifolds

• Shut-off devices

• Installation guide and fastenings

• Transition joints from polypropylene to metal, or from metal to polypropylene

Questions that customers often ask about AQUATHERM BLUE

You can use aquatherm blue in heating system construction, for connection of heating and cooling, for underfloor heating, for industrial floor cooling and heating, for refrigeration, in agriculture, for sports floor heating/cooling, in swimming pool technology, for chemical transport and in shipbuilding.

We offer numerous types of tubes. You will find a detailed overview of all variants on this page under the item product types.

Your aquatherm contact person is at your disposal for further information or specific project inquiries.

The aquatherm polypropylene pipe systems comply with the requirements of the fire classification B2 DIN 4102 (normal inflammable). Compared to natural products like wood, cork or wool, aquatherm polypropylene pipes do not produce any gas toxicity. In case of fire, there is no risk of dioxin emissions.

To avoid fire and smoke transmission aquatherm advises the use of fire retardant seals. The fire resistance period is the minimum period in minutes. The extent of the preventive measures depends on the type of installation. The determining of fire areas and fire classification has to be made in accordance with the law of the country. Information is given by the Planning Department and Building Control Office or the Fire Protection Representative.

Basically fire walls and ceilings with pipe passages have to be installed to the same fire resistance classification. All fire protection systems with a corresponding classification are suitable for aquatherm polypropylene pipes.

The following companies offer suitable fire protecion solutions:

Brandschutzrohrschale

Conlit 150 U:

DEUTSCHE ROCKWOOL

GmbH & Co. KG

Rockwool Straße 37-41

45966 Gladbeck

Tel: +49 2043 408 0

www.rockwool.de

Brandschutzmanschette

AWM II:

Flamro Brandschutz

Vertriebs GmbH

Am Sportplatz 2

56291 Leiningen

Tel. +49 6746 9410-0

Mail: info(at)flamro.com

www.flamro.de

Hilti Deutschland AG

Hiltistrasse 2 · 86916 Kaufering

Tel: +49 800 888 · www.hilti.de

Planning:

- TrinkwV-2000 Regulation for Potable Water

- DIN 2000 Central drinking water supply-Guidelines regarding requirements for drinking water, planning, construction,operation and maintenance of plants

- EnEV Decree for Energy Saving

- DIN 1988 Standard for Potable Water Installations

- ISO 10508 Plastic pipe systems for hot and cold water installation – Guideline for classification and dimensioning

- All provided pipe-systems correspond to the technical conditions of the application classes acc. to ISO 10508 for the field of potabel water and heating. aquatherm green pipe for the classes 1, 2 (potable water), aquatherm blue pipe for the classes 4 and 5 (heating).

- For the application of the classification system (acc. to ISO 10508) the national regulations and the manufacturer¢•s instructions must be considered.

- DIN 4109 Standard for the Elimination of Noise in the Field of Structural Engineering

- DIN 18381 Installation of Gas, Water and VOB Part C Sewage Pipes inside Buildings

- DIN 16928 Pipe Connections, Fittings, Installation

- DVS 2207 Welding of Thermoplastics

- DVS 2208 Welding Machines and Devices for Thermoplastics

Systemspecific standards:

- General quality requirements, dimensions

- DIN 8077 Polypropylene (PP) Pipes, Dimensions

- DIN 8078 Polypropylene (PP) Pipes, General Quality Requirements

- DIN 16962ff Pipe Joint Assemblies and Fittings for Polypropylene Pressure Pipes

- DIN EN ISO 15874ff Plastic pipe systems for hot and cold water installation; polypropylene

- DVGW-Working sheets

- SKZ-Guidelines

- DIN EN ISO 9000 ff.

Systemspecific standards: Hygiene

BfR Federal Institute for risk assignment

- Health assessment of plastics and non-metallic materials within the framework of the law for foods and commodity goods for potable water applications

DVGW-working sheet W 270

- Increase of Microorganism on Materials. Used for Potable Water Applications – Test and Evaluation BS 6920

- “Suitability of non-metallic products for use in contact with water intended for human consumption with regard to their effect on the quality of water.”

- Local regulations and codes of practice must be observed. The same goes for regulations regarding the use of chemicals.

- *(Additional regional decrees and recommendations are disregarded.)

aquatherm polypropylene pipes may be stored outside at any temperature. A solid base for the pipe is very important to avoid a deformation of the pipes while in transport and storage.

At temperatures below 0 °C it is possible to damage the pipes through strong impacts. The material has to be treated with caution at low temperatures. Inspite of its high resistance aquatherm pipes should be treated with care. UV-radiation has effects on all high polymer plastics. Do not store permanently outdoor. The maximum permissible storage time outdoors is 6

months.