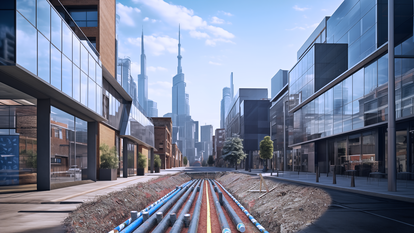

A sustainable district heating network is particularly interesting for local authorities and companies that want to improve their carbon footprint and become independent of fossil fuels in the long term. However, with the expansion of such systems across Germany, the requirements are also growing: Pipelines must not only be efficient and durable, but also environmentally friendly, economical, and flexible in use.

Requirements for district heating pipework

In modern district heating networks, pipelines are subjected to extreme thermal and mechanical loads. In addition to consistently high operating temperatures and fluctuating pressure conditions, they must also reliably withstand external environmental influences - and do so for decades.

Particularly relevant are requirements such as:

- Highly effective insulation to minimise heat loss

- Reliable sealing systems

- Effective corrosion protection

- Overall high energy efficiency of the pipework system

While traditional materials such as steel often result in high installation and maintenance costs, piping systems made of polypropylene, such as those developed by aquatherm, offer a future-proof alternative. They are particularly advantageous for the construction and expansion of district heating networks due to their ease of use and long-term durability. Thanks to fusion technology, the pipes can be welded quickly, safely, and with a permanently tight seal - without the use of naked flames. This ensures maximum operational safety and a long service life with minimal maintenance.

Neighbourhood solutions, municipal utilities, schools, and public buildings benefit from a reliable, long-lasting heat supply with aquatherm systems. The simple installation, long service life and high energy efficiency make the systems ideal for municipal infrastructure projects focusing on renewable energies.

Constant operating temperatures and high supply reliability are essential in business parks, industrial facilities, and data centres. In these settings, aquatherm stands out with robust pipework systems that withstand high loads and ensure long-term operational reliability.

aquatherm supports planners and suppliers in the expansion of existing networks - both technically and through expert advice. The systems can be easily integrated into hybrid energy solutions and offer a sustainable approach to transforming heating infrastructure.

AQUATHERM ENERGY: The right pipework for district heating

The innovative system was specially developed for modern district heating infrastructures and combines technological precision with the sustainable use of materials. The three-layer structure - consisting of PP-RCT carrier pipe, PUR insulation, and HDPE jacket - ensures maximum energy efficiency and protection while being lightweight and highly flexible during installation.

Thanks to its high chemical and thermal resistance and uncomplicated processing, aquatherm energy offers a future-proof solution for cities, municipalities, and energy suppliers - “Made in Germany”, reliable and designed for longevity. It is ideal for use in district heating networks.

Practical projects: District heating networks with AQUATHERM

Restrictions and costs minimised thanks to aquatherm pipework system - Gateshead is a town in the north-east of England with a population of around 202,419. It is known for its architecture, including the "Sage Gateshead", the "Angel of the North" and the "Baltic Centre for Contemporary Art". In 2017, Jesse Norman, the UK Minister for Industry and Energy, unveiled a ground-breaking energy scheme designed to cut energy bills and carbon emissions for homes and businesses in Gateshead.

In Veksø, north of Copenhagen, a pioneering district heating project is being built that will connect around 400 households to an energy-efficient network. The centrepiece is a 15-kilometre-long, well-insulated pipe system that minimises heat loss and thus reduces the energy requirements of the combined heat and power plant. The pre-insulated plastic pipe aquatherm energy bluewhich is also used in this project thanks to its high insulation performance, corrosion resistance and environmental friendliness.

Frequently asked questions about the district heating network with AQUATHERM

A connection is especially worthwhile in new development areas, neighbourhood heating solutions, or municipal renovation projects - essentially, wherever multiple buildings can be efficiently supplied with heat together.

The CO₂ costs are significantly lower than those of fossil heating systems - especially when using renewable energy sources. According to the Federal Environment Agency (2024/2025), district heating in Germany generates between 198 and 254 g CO₂/kWh, depending on the network. By comparison, gas heating systems emit around 247 g CO₂/kWh and oil heating systems around 318 g CO₂/kWh.

District heating is also competitive in terms of price. A recent analysis of 576 heating networks (vzbv, April 2025) shows a nationwide median price of 17 Ct/kWh (gross). Approximately 27% of these networks have prices above 20 Ct/kWh, and just under 9%exceed 25 Ct/kWh. Despite this, district heating generally offers greater price stability compared to fossil fuel heating systems, as it is significantly less impacted by CO₂ price increases.

(Source: Federation of German Consumer Organisations (2025))

Typical challenges include high initial investment costs, civil engineering work in existing buildings, coordination of subsidies, and the integration of renewable energy sources into existing systems.

By incorporating renewable heat sources, modular pipework systems like polypropylene, digital network controls, and thermal storage, a district heating network can be designed efficiently and sustainably to meet future demands.